Technical Textile Firms in India

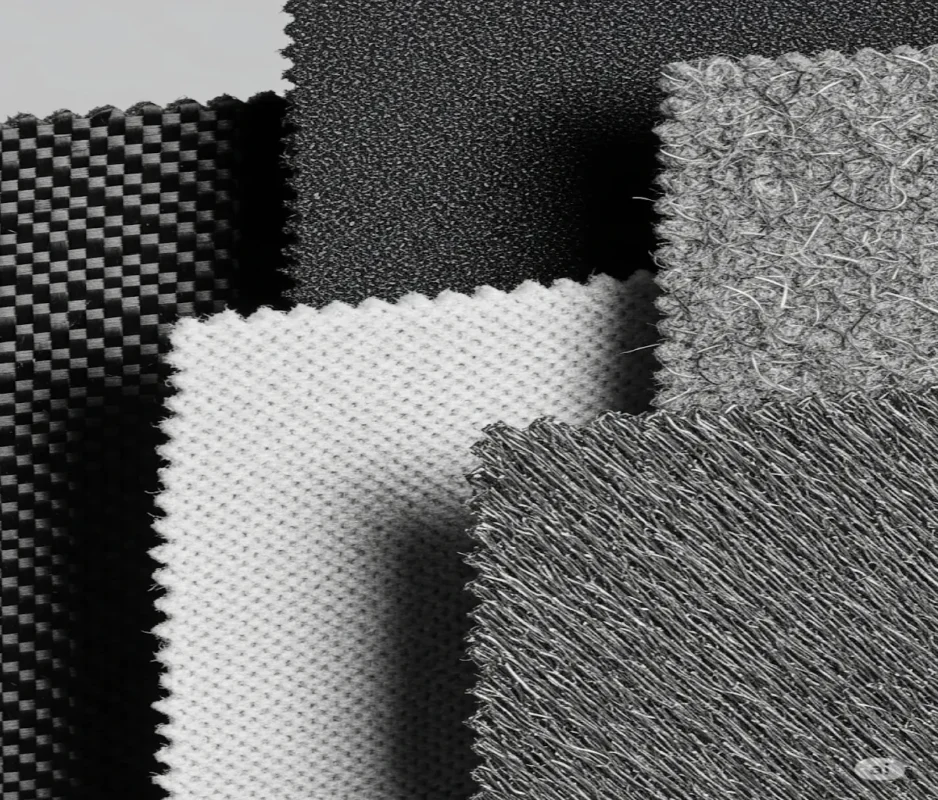

What are Technical Textiles?

Technical textiles are textile supplies and merchandise manufactured primarily for his or her technical efficiency and practical properties quite than aesthetic or ornamental traits.

These textiles are engineered for particular functions similar to safety, reinforcement, filtration, medical use, or geotechnical efficiency. They usually incorporate superior fibers, coatings, or composites.

Technical Textiles Purposes

| Phase | Use Space Instance |

| Agrotech | Crop covers, shade nets, mulch mats |

| Buildtech | Concrete reinforcement, facade membranes |

| Clothtech | Interlinings, stitching threads, insulation |

| Geotech | Street stabilization, landfills, and drainage |

| Hometech | Upholstery, mattress parts, blinds |

| Indutech | Conveyor belts, filtration materials, and insulation |

| Meditech | Surgical robes, wound dressings, masks |

| Mobiltech | Seat belts, airbags, and inside trims |

| Oekotech | Oil spill management, filtration, and air pollution management |

| Packtech | Versatile packaging, FIBC baggage, wrappings |

| Protech | Fireplace-retardant fits, bulletproof vests |

| Sportech | Parachutes, sportswear, tents |

India’s Technical Textiles Trade

India’s technical textiles {industry} is present process a silent revolution, propelled by rising international demand, strategic authorities interventions, and evolving commerce partnerships. As soon as a distinct segment sector confined to industrial functions, technical textiles have now emerged as a high-potential, innovation-driven market poised to play a key function in India’s $1 trillion manufacturing ambition.

Knowledge Heart Associated Articles

Market Measurement & Progress Potential

Globally, the technical textile market stood at USD 220–240 billion in 2023 and is anticipated to develop at a CAGR of 5.5–6.2%, reaching USD 320–340 billion by 2030. These textiles are more and more being adopted throughout sectors like healthcare, automotive, infrastructure, agriculture, protection, and sports activities, owing to their superior efficiency traits—energy, sturdiness, warmth resistance, filtration, and antimicrobial properties.

India’s market is rising quicker than the worldwide common, at the moment valued at USD 22–23 billion in 2023, and projected to develop at a CAGR of 9–10%. The federal government has set an formidable goal of USD 40–50 billion by 2030, pushed by each home consumption and exports.

| Metric | Worth |

| Present Market Measurement (2023) | USD 22–23 billion |

| Projected Measurement (2030) | USD 40–50 billion |

| CAGR | 9–10% |

| Export Worth (2023) | USD 2.5–3 billion |

| Key Export Segments | Packtech, Meditech, Agrotech |

Nationwide Technical Textiles Mission (NTTM)

Nationwide technical textiles mission launched in February 2020 with and funds outlay of Rs 1480 crore. The target of this mission was to place India as a worldwide chief in technical textiles by rising home consumption and exports, decreasing dependency on imports of high-performance specialty fibers, selling R&D, innovation, and skilling in technical textiles, and standardizing product classes via BIS certification.

Recognizing the sector’s strategic significance, the Authorities of India launched a Manufacturing Linked Incentive (PLI) scheme in 2021 with an outlay of ₹10,683 crore to spice up the home manufacturing of high-value technical textiles and specialty fibers.

PLI Scheme Options:

- Covers 40+ superior product classes similar to anti-microbial fibers, aramid yarns, carbon composites, and so forth.

- Encourages funding in practical materials, nonwovens, and coated textiles.

- Supplies monetary incentives based mostly on incremental gross sales over 5 years.

- Targeted on import substitution, R&D, and job creation.

PM MITRA Parks:

To additional catalyze scale and innovation, the federal government has additionally introduced seven PM MITRA (Mega Built-in Textile Area and Attire) parks throughout key textile-producing states. These parks provide:

- Plug-and-play manufacturing infrastructure

- Widespread amenities, logistics, testing labs, and incubation facilities

- Attractiveness for FDI and expertise switch

India’s energetic pursuit of Free Commerce Agreements (FTAs) with main developed markets just like the UK and the USA is anticipated to open new export channels for technical textile gamers.

UK-India FTA (Anticipated 2025):

- Technical textiles are recognized as a dawn sector below dialogue.

- India goals to achieve preferential entry for Packtech, Agrotech, and Protecting clothes.

- UK consumers are more and more searching for China+1 options, giving Indian companies a strategic edge.

USA-India Commerce Cooperation:

- The USA is among the many prime 3 importers of high-performance Meditech and Indutech merchandise.

- Indian companies can profit from relaxed import duties, expertise collaboration, and sourcing tie-ups.

- The Indo-Pacific Financial Framework (IPEF) could additional combine India into international PPE and protection textile provide chains.

Traditionally, India imported most of its high-performance materials and specialty fibers. However the panorama is altering quickly:

- Over 90% of India’s PPE demand (Private Protecting Gear. Refers to protecting clothes and equipment made utilizing superior textile supplies, usually categorized below the Meditech and Protech segments, and is now met via home manufacturing.

- Indian technical textile exports have expanded to over 80 nations, with robust traction within the Center East, Africa, and Southeast Asia.

- With PLI-backed manufacturing, MITRA parks, and international market entry through FTAs, India is well-positioned to develop into a prime 5 international participant by 2030.

Technical Textile firms in India

Allow us to analyse the technical textile firms in India which are altering the form of this {industry}. Under are prime 6 technical textile producers in India which are shaping this section.

Garware Technical Fibres

GTFL is a number one Indian producer of technical textiles with international management in aquaculture options, fishing nets, and a rising presence in geosynthetics. The corporate exports to over 75 nations and delivers high-margin, value-added, custom-engineered fiber-based merchandise.

Garware is a part of the Protech, Agrotech, and Geotech classes in technical textiles. Although the corporate shouldn’t be coated below the PLI scheme immediately due to its focus at the moment on high-value artificial fiber manufacturing, it’s well-aligned with the Nationwide Technical Textile Mission (NTTM) because of its software in infrastructure, aquaculture, and environment-related segments, similar to PM Gati Shakti and Bharatmala and so forth.

Key Progress Triggers & Timeline

| Progress Set off | Key Particulars | Timeline | Impression |

| Margin Growth | Important shift towards value-added merchandise throughout geosynthetics and aquaculture. Robust pricing energy from modern, custom-made options. EBITDA margin improved by 22% YoY. | FY 2023–24 | Greater profitability with PAT crossing ₹200 crore |

| Capability Growth | Whereas not explicitly detailed in numbers, the corporate hints at increasing home and export-oriented product strains, particularly in geosynthetics and sports activities segments. | Ongoing | Helps elevated product vary and quantity development. |

| Home Market Refocus | Re-emphasis on the Indian market through reservoir lining, landfill capping, and erosion management. Focusing on margins and market share from native suppliers. | FY 2023–24 onwards | Improves utilization of home demand, insulation from international volatility |

| Geographical Growth | Strengthened footprint in Southern Europe, Central America, and South America. Export-led demand continues to dominate, with ~70% of income from exports. | FY 2023–25 | Enhances international market share and overseas foreign money earnings |

| Course of Effectivity | Continued optimization in manufacturing—decrease prices, higher turnaround instances, and automation. | FY 2023–24 | Improved margins and money move |

Monetary Snapshot (FY 2023–24)

| Metric | Worth | Progress |

| Income | ₹1,325 crore | +2% YoY |

| EBITDA | ₹315 crore | +22% YoY |

| PBT | ₹272 crore | +22% YoY |

| PAT | > ₹200 crore | Milestone achieved |

| Dividend | ₹3.00/share | 30% payout |

Banswara Syntex Ltd

Banswara Syntex Ltd is a vertically built-in textile firm with operations spanning spinning, weaving, dyeing, and garmenting. It has a robust presence in polyester-viscose blends, suiting materials, and technical textiles (fire-retardant materials, efficiency put on), serving home and export markets (notably Europe and the US).

Banswara Syntex Ltd is transitioning from a commodity textile participant to a high-margin technical and efficiency textile exporter, backed by vertical integration, disciplined capex, and price effectivity via renewable vitality adoption. Continued deal with garmenting and practical textiles makes it a robust candidate for margin-led development over FY25–FY27.

Progress Set off Evaluation (FY24–FY25)

| Progress Set off | Statement | Timeline | Impression |

| Margin Growth | Deal with value-added merchandise (efficiency materials, technical textiles, practical clothes). Growing share of clothes within the product combine | Ongoing | Constructive impression on EBITDA margin |

| Capability Growth | Added new machines in weaving and dyeing, increasing garmenting capability | FY24–FY26 | Helps larger quantity and value-added product scale |

| Deleveraging | Lowered debt and improved curiosity protection; debt-to-equity improved from 1.35x (FY23) to beneath 1.20x (FY25 goal) | FY24–FY25 | Improves money move & creditworthiness |

| Capex | Ongoing capex of ₹90–100 Cr for equipment automation, garment unit growth, and renewable vitality | FY24–FY26 | Enhances scale, reduces vitality value |

| Geographical Growth | Strengthened presence within the US and Europe for high-value practical put on | Ongoing | Elevated exports & model visibility |

| Backward Integration | In-house yarn and material manufacturing; photo voltaic vitality funding to chop energy prices | Photo voltaic: FY24–FY25 | Price optimization, sustainability |

Sanrhea Technical Textiles Ltd

Sanrhea Technical Textiles Ltd is a specialised producer of business materials, with a deal with chafer materials, flame-retardant materials, para-aramid reinforcement materials, and liner materials primarily utilized in tyre manufacturing, rubber hoses, conveyor belts, and protection functions. It has carved a distinct segment in high-performance woven materials catering to international technical textile functions.

Sanrhea is a extremely centered, area of interest technical textile firm with specialization in reinforcement and flame-retardant materials for the tyre, rubber, and protection industries. Regardless of FY24 challenges, its product positioning, low debt, and technical know-how make it a secure, albeit small, candidate for export-led restoration in FY25–FY27.

Progress Set off Evaluation (FY23–24)

| Progress Set off | Statement | Timeline | Impression |

| Margin Growth | Improved product combine (from base chafer to high-value reinforcement materials), however the margin was below strain because of enter value volatility and international demand droop. | Partially seen in FY24 | Medium-term margin uptick anticipated as exports revive |

| Capability Growth | No main greenfield or brownfield growth reported; deal with modernization and high quality enhancement. | Ongoing | Deal with effectivity, not quantity growth |

| Deleveraging | The corporate stays conservatively leveraged with restricted long-term debt; short-term borrowing is aligned with working capital. | FY24 | Maintains monetary stability |

| Capex | Restricted capex centered on course of modernization, vitality effectivity, and product R&D | FY23–24 | Enhances working efficiency quite than top-line growth |

| Geographical Growth | Exports have been sluggish in FY24 because of macro headwinds; the corporate stays centered on the protection sector, abroad tyre producers, and rubber {industry} purchasers. | Exports to recuperate FY25+ | Rebound anticipated from Europe and the US in FY25. |

Strategic Turning Factors

| 12 months | Occasion |

| FY22–FY23 | Focus started shifting towards high-value flame-retardant and defense-grade materials. |

| FY23–FY24 | Slowdown in exports and margin strain highlighted the necessity to stabilize enter prices. |

| FY25 (Anticipated) | Export market revival + potential order pickup from protection/Rubber OEMs |

Monetary Snapshot – FY 2023–24

| Metric | Worth |

| Income | ₹43.45 Cr |

| PAT | ₹1.35 Cr (down from ₹2.79 Cr YoY) |

| EBITDA Margin | Below strain (enter value volatility) |

| Debt | Low, manageable working capital limits |

Arvind Restricted

Arvind Restricted, historically recognized for its denim and attire material legacy, is quickly reshaping its id via centered funding in technical textiles below its Superior Supplies Division (AMD). The corporate is positioning itself on the intersection of high-performance supplies, sustainability, and industry-specific innovation—with functions spanning protection, automotive, industrial safety, and infrastructure.

Arvind Restricted’s Superior Supplies Division (AMD) generated ₹580 crore in FY25, with plans to scale it to ₹1,000+ crore over the subsequent 5 years. Backed by a ₹400–500 crore capex plan, a robust push into protection, industrial, and sustainable technical textiles, and the round fiber JV with PurFi, AMD is evolving right into a high-growth, high-margin pillar of Arvind’s long-term technique.

Capex-Backed Progress

Arvind is investing ₹400–500 crore to broaden the AMD, aiming to cater to sectors similar to protection textiles, aerospace, and industrial filtration. The main focus is on proprietary, application-specific improvements—a key differentiator in India’s technical textile panorama.

Circularity and Backward Integration

A essential strategic transfer is the three way partnership with PurFi International, geared toward producing 3,500 MT of round, regenerated fibers yearly from post-consumer waste. The plant in Gujarat is designed to scale over 4 years, guaranteeing uncooked materials resilience and aligning with sustainability mandates from international consumers.

Future development potential

· In FY 2024–25, the AMD contributed ~₹580 crore, representing about 9.3% of Arvind Restricted’s whole revenues.

· The section has grown steadily at ~10–12% CAGR over the previous couple of years, regardless of macroeconomic volatility.

· Gross margins are considerably larger than conventional textiles because of custom-made, high-performance functions.

Welspun Residing Restricted

Welspun Residing Restricted is quick rising as a centered participant within the technical textiles section, which is a key a part of its “Rising Companies” portfolio. In FY24, superior textiles contributed ~5% of whole revenues, reaching ₹449 crore, with 29% YoY development, signaling robust momentum.

Core Capabilities & Purposes

Welspun’s technical textiles are largely non-wovens, leveraging applied sciences similar to:

- Spunlace (27,729 MT capability) – Utilized in hygiene, wipes, and medical disposables.

- Needlepunch (3,026 MT) – For filtration, protecting attire, and auto parts.

- Moist Wipes (100 million packs) – Bought below B2B and personal label fashions.

The section companies high-value export markets such because the US, Europe, and the Center East, with Welspun being India’s largest Spunlace exporter.

Welspun is strategically specializing in scaling B2B technical textile gross sales and increasing into protecting put on, filtration, and wellness materials. With a robust manufacturing spine and ESG-compliant practices, it’s well-placed to learn from the worldwide shift towards sustainable, high-performance textiles.

Phase Snapshot (FY24)

- Applied sciences: Spunlace (27,729 MT), Needlepunch (3,026 MT), and Moist Wipes (100 Mn packs)

- Utilization: 59% for Spunlace, 48% for Needlepunch, 21% for Wipes — indicating ample headroom for scale-up

Welspun is strategically specializing in scaling B2B technical textile gross sales and increasing into protecting put on, filtration, and wellness materials. With a robust manufacturing spine and ESG-compliant practices, it’s well-placed to learn from the worldwide shift towards sustainable, high-performance textiles.

Vardhman Textiles

Vardhman Textiles Ltd, a serious built-in textile producer recognized for its yarns and materials, is step by step constructing a basis for entry into technical textiles, significantly within the efficiency materials and value-added processing area. Although not but a dominant income driver, technical textiles are rising as a part of its medium- to long-term diversification technique.

Vardhman is within the early levels of evolving from a commodity-focused textile main to a value-added resolution supplier, with technical and efficiency textiles as a part of its future roadmap. With the correct capex already underway and a robust fame in high quality and scale, Vardhman is laying the groundwork for its technical textile ambitions over the subsequent 3–5 years.

Capex & Functionality Alignment

- A big capex plan (~₹1,300 crore) was introduced in FY22 for yarn and material growth.

- A portion of this funding goes into modernizing processing and ending applied sciences, particularly related to technical textiles.

- Whereas the report doesn’t get away a income determine for technical textiles, there may be rising emphasis on product customization and R&D, that are stepping stones towards practical textiles.

Remaining phrases on Technical Textiles

India’s technical textiles sector is not a distinct segment—it’s quick changing into a spine of the nation’s industrial and export ecosystem. Backed by robust coverage assist via the Nationwide Technical Textiles Mission, PLI schemes, and PM MITRA parks, the {industry} is on monitor to greater than double its market measurement by 2030. What units this development aside is the standard of momentum—pushed not simply by quantity, however by margin-rich, high-performance functions throughout protection, infrastructure, and sustainability. With leaders like Garware, Arvind, and Welspun scaling up value-added merchandise and exports, and newcomers like Sanrhea and Banswara sharpening their focus, India is positioned to emerge as a worldwide powerhouse in technical textiles—competing on innovation, not simply value.