Bulk metallic glass World market dimension and Key Producers

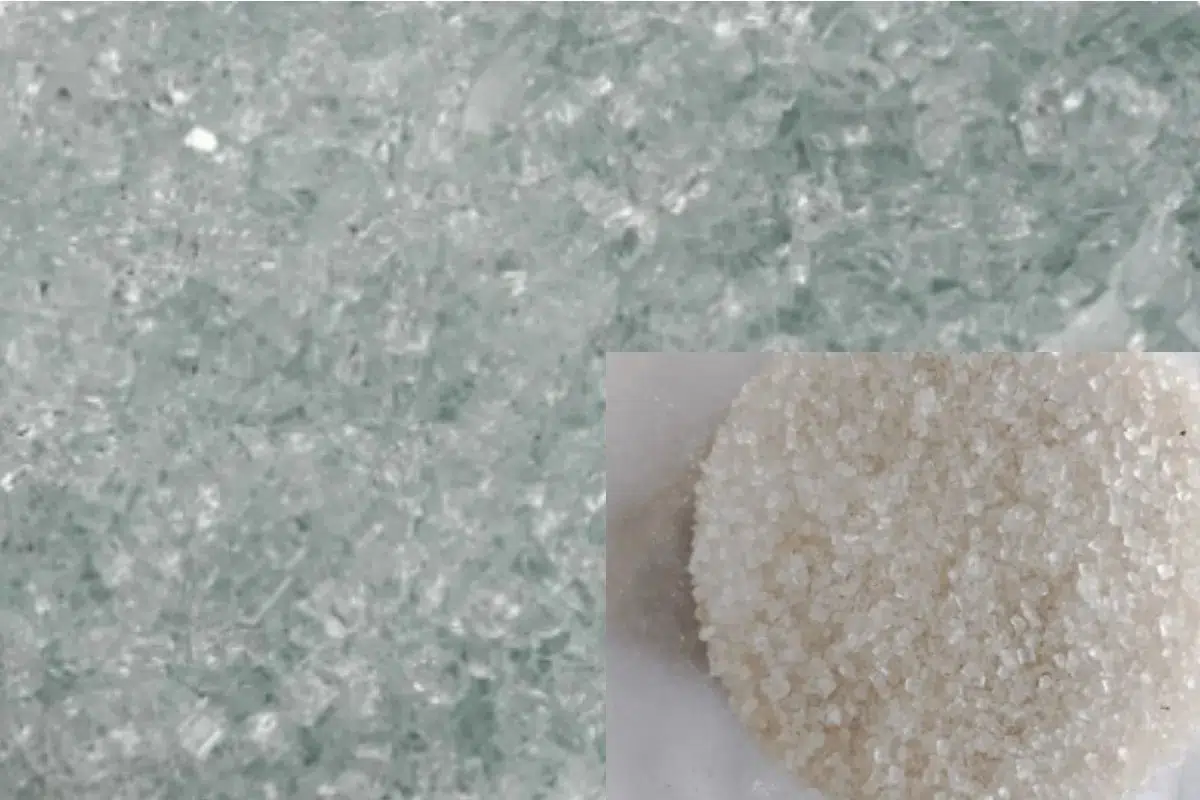

Bulk Metallic Glass (BMG), also referred to as amorphous steel, has been an interesting improvement in supplies science, combining the properties of each metals and glasses. With its distinctive molecular construction and spectacular properties like excessive energy, corrosion resistance, and elasticity, BMG has turn into more and more beneficial throughout numerous industries. This text delves into the majority metallic glass market, overlaying its present dimension, main producers, manufacturing processes, and purposes, all of which form the way forward for this exceptional materials.

The worldwide bulk metallic glass market has skilled regular development over the previous decade as a result of growing demand for high-performance supplies. As of 2024, the Bulk metallic glass international market dimension is estimated to be valued between $80 million and $100 million, with an anticipated compound annual development fee (CAGR) of round 10 – 15% over the subsequent 5 years. Development is pushed primarily by the increasing purposes of BMG in industries corresponding to electronics, medical units, automotive, and aerospace, the place sturdiness, elasticity, and corrosion resistance are essential.

The Asia-Pacific area holds a big share of the majority metallic glass market, with international locations like Japan, China, and South Korea main in manufacturing and consumption. North America and Europe are additionally main contributors, with robust R&D investments in BMG expertise for high-tech industries. The market’s development trajectory is anticipated to stay optimistic as these areas proceed to spend money on the event and commercialization of BMG throughout rising industries, making this a profitable sector for producers and traders alike.

The manufacturing of bulk metallic glass entails advanced manufacturing processes, and solely a handful of corporations specialize on this materials. The main bulk metallic glass producers embody:

- Materion Company – Based mostly in america, Materion is a one of many main bulk metallic glass producers primarily in superior supplies, and it produces bulk metallic glass for numerous purposes, together with aerospace and electronics. The corporate income is principally segmented as under.

Efficiency Supplies: This phase focuses on beryllium and non-beryllium alloy programs, engineered elements, and beryllium hydroxide. In 2023 and 2022, Efficiency Supplies accounted for 45% and 38% of the corporate’s complete web gross sales, respectively.

- Beryllium oxide (BeO) can be utilized as a part in sure glass formulations, notably in specialised optical and scientific glasses. Bulk glasses containing beryllium compounds are generally utilized in environments that demand excessive thermal stability and wonderful transmission of ultraviolet mild.

Digital Supplies: This phase focuses on superior chemical substances, microelectronics packaging, and numerous steel merchandise utilized in semiconductors, shows, and different purposes. Digital Supplies generated 48% and 55% of complete web gross sales in 2023 and 2022, respectively

Precision Optics: This phase designs and produces skinny movie coatings, optical filters, and assemblies for numerous industries, together with life sciences, aerospace and protection, and shopper electronics. Precision Optics contributed 6% of web gross sales in each 2023 and 2022

Different: This phase represents unallocated company prices and doesn’t straight relate to particular supplies or merchandise. It accounted for lower than 1% of complete web gross sales in 2023 and a negligible quantity in 2022

- Hitachi Metals, Ltd. – A pacesetter in supplies expertise and bulk metallic glass producers, Hitachi Metals manufactures quite a lot of BMG alloys, specializing in purposes in automotive, electronics, and industrial tools.

- The corporate has a powerful concentrate on creating new BMG alloys with improved properties, corresponding to greater energy, higher corrosion resistance, and enhanced formability.

- Hitachi Metals presents a spread of BMG merchandise, together with rods, plates, and custom-shaped elements.

- Heraeus Holdings is a significant bulk metallic glass producers, notably recognized for its experience in specialty glasses. Heraeus produces high-purity optical glasses utilized in numerous purposes, together with – Cameras and lenses, Microscopes and telescopes, Medical units, Laser expertise, and Optoelectronic units.

- Heraeus is a number one producer of high-purity quartz glass, which is important for industries corresponding to Semiconductor Manufacturing, Telecommunications, and Photo voltaic power. Lighting.

- Eutectix LLC is likely one of the main bulk metallic glass producers that makes a speciality of the manufacturing of bulk metallic glass (BMG) alloys, also referred to as amorphous glass-forming alloys. Eutectix manufactures quite a lot of zirconium-based BMG alloys. They provide these alloys in numerous kinds, together with rods, tubes, and plates.

- These BMGs are utilized in numerous purposes, corresponding to Medical units, Aerospace elements, Automotive elements, Sporting items, and Electronics.

- Glassimetal Know-how Inc. is among the many main bulk metallic glass producers focuses on creating and manufacturing bulk metallic glasses (BMGs), also referred to as glassy metals. Glassimetal has developed a spread of proprietary metallic glass alloys, together with GlassiNickel, GlassiZirconium, GlassiSteel, GlassiGold, and GlassiPlatinum.

- Glassimetal’s supplies have potential purposes in numerous sectors, together with Aerospace, Medical, Electronics, and Automotive.

These corporations make investments closely in analysis and improvement to create custom-made BMG alloys that meet particular trade wants, driving innovation and competitors throughout the bulk metallic glass market.

The distinctive properties of bulk metallic glass are largely as a consequence of its non-crystalline construction, which differs considerably from conventional metals. Bulk metallic glass manufacturing course of entails a producing course of that forestalls crystallization, leading to a fabric with an amorphous construction that imparts excessive energy, elasticity, and corrosion resistance. Right here’s a better have a look at the majority metallic glass manufacturing course of:

- Alloy Choice and Composition

Step one in bulk metallic glass manufacturing course of is choosing the correct steel alloys. Widespread parts in BMG embody zirconium, titanium, copper, nickel, and aluminum. These alloys are chosen for his or her skill to type a secure amorphous construction, which requires cautious balancing of the alloy’s chemical composition. - Fast Cooling Course of

The core of bulk metallic glass manufacturing course of is the fast cooling or “quenching” course of. In conventional steel casting, molten steel cools slowly, permitting atoms to type a crystalline construction. Nonetheless, in BMG manufacturing, the molten alloy is cooled at an especially quick fee, usually over 1,000 levels Celsius per second. This fast cooling “freezes” the atoms in a disordered state, stopping crystallization and leading to an amorphous or glass-like construction. - Injection Molding

For bulk manufacturing, BMG is usually formed utilizing injection molding. The alloy is melted and injected right into a mildew, the place it quickly cools and solidifies right into a desired form. Injection molding permits for exact shaping and minimal materials wastage, making it supreme for industries that require intricate designs. - Floor Remedy and Ending

After molding, BMG supplies might bear further floor therapies, corresponding to sprucing or coating, to reinforce properties like put on resistance and aesthetic attraction. This step is especially essential for shopper electronics and medical units, the place floor high quality is important.

The manufacturing means of BMG is very specialised, requiring precision and management at each stage. Though advanced, this course of is vital to producing bulk metallic glass with its attribute energy, flexibility, and corrosion resistance, setting it other than standard metals.

Additionally Learn

Due to its distinctive mixture of properties, bulk metallic glass has a various vary of purposes throughout a number of industries. Listed here are a few of the most notable makes use of:

- Client Electronics is one of the fastest-growing purposes of bulk metallic glass is in shopper electronics. BMG’s energy, sturdiness, and resistance to scratching make it supreme for producing casings and frames for smartphones, tablets, and wearables. Its amorphous construction additionally permits for intricate designs, which attraction to producers aiming for smooth, premium aesthetics in units. Firms like Apple have even explored utilizing BMG for sturdy system casings, which underscores its attraction in high-end electronics.

- Bulk metallic glass 3d print, and it’s gaining consideration as a revolutionary materials in additive manufacturing. The distinctive atomic construction of BMG permits it to be molded and formed with out the restrictions of crystalline grain buildings present in conventional metals. This makes it supreme for 3D printing advanced geometries with excessive precision and minimal materials waste. Bulk metallic glass 3d print leverages the fabric’s energy, elasticity, and corrosion resistance, producing elements which can be each light-weight and sturdy, which is particularly helpful in industries like aerospace, medical units, and shopper electronics.

- Medical Units

The medical trade advantages vastly from the biocompatibility and corrosion resistance of bulk metallic glass. BMG is utilized in surgical devices, implantable units, and medical tools the place energy and sturdiness are important. Its non-corrosive properties make it appropriate for units that want to face up to the cruel environments of the human physique, together with orthopedic implants and dental purposes. - Automotive and Aerospace

In each the automotive and aerospace industries, light-weight but robust supplies are important for bettering gas effectivity and security. Bulk metallic glass presents excessive strength-to-weight ratios, making it supreme for numerous elements in these sectors. In aerospace, BMG can be utilized in structural elements, fasteners, and gears, the place its excessive elasticity and put on resistance are essential. The automotive trade additionally makes use of BMG for elements that have excessive put on and tear, corresponding to gears and engine elements. - Sporting Items

The elasticity and energy of bulk metallic glass have additionally discovered purposes within the sports activities trade. BMG is utilized in golf golf equipment, tennis rackets, and different sporting tools the place energy, affect resistance, and exact weight distribution are important. For instance, BMG-based golf golf equipment present elevated energy and accuracy as a result of materials’s distinctive mechanical properties. - Industrial Equipment

Industrial purposes of bulk metallic glass embody manufacturing molds, dies, and different elements that require hardness and put on resistance. BMG’s sturdiness permits it to face up to the high-stress environments typical in industrial settings, bettering the longevity of kit and lowering the necessity for frequent replacements. - Power Storage and Batteries

Within the power sector, BMG supplies are being explored for battery applied sciences and power storage programs. The excessive elasticity and energy of BMGs are helpful in batteries the place versatile buildings and resistance to degradation are wanted, notably in purposes like electrical autos.

Future Outlook and Market Alternatives for Bulk Metallic Glass

The way forward for the majority metallic glass market appears to be like promising, with technological developments and growing demand throughout numerous industries driving development. As industries proceed to hunt supplies that supply superior efficiency over conventional metals, BMG is well-positioned to satisfy this demand. Future developments in manufacturing processes, corresponding to superior injection molding strategies and the introduction of less expensive alloy compositions, are anticipated to cut back manufacturing prices, additional broadening BMG’s applicability.